Are you maximizing the value of your asset base?

If you could operate your plant 24/7 for one year, make 100% quality product at 100% maximum rate and 100% target yield – how much profit would your organisation make?

Continuous Improvement is about improving your business processes and quality performance. Poor business processes result in waste, poor quality products and unnecessary costs. Asset Utilisation is one element of continuous improvement, it is both a measurement and a business process that when implemented can improve plant throughput whilst using the existing asset base. An increase in asset utilisation can generate free capacity, avoid capital costs, and reduce operating costs, all of which are crucial for survival in the current climate.

What’s even better is the benefits in focusing on asset utilisation generally come with no significant extra costs, unless of course, the existing capacity is inadequate to meet customer demand.

Increased sales are probably the biggest winner by maximising your production lines free capacity and unlocking the ‘hidden profit’ on your production line.

Other spin-offs for maximising asset utilisation and improving the consistency of operation is a reduction in the number of stop/starts on a production line, which can often lead to increased wear and tear on equipment, resulting in increased maintenance expenditure. When equipment fails this does impact plant availability and can reduce the capacity output of a line.

So, where do we start?

We need to first understand the concept of asset utilisation and be familiar with production line capability.

Asset utilisation is about understanding the gap between how the plant is currently performing and the absolute best it can perform. So, we need to know the nameplate capacity of our production line along with any historical best production runs to understand what number we are going to measure against. If we recognise that we have a low asset utilisation number and the production line is making money, then we have an opportunity to make more profit.

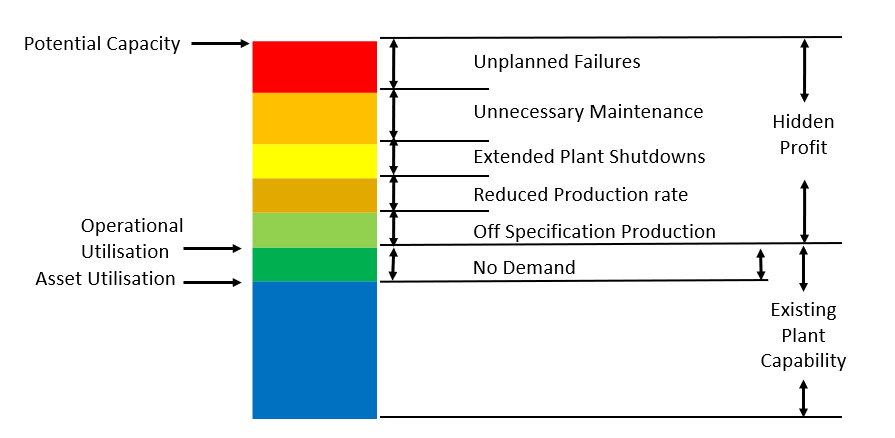

To understand the concept of the ‘Hidden Profit’ we need to look at the losses that will negatively affect the production lines capability. See Figure 1 ‘Hidden Profit’

These losses are usually attributed to:

- No Demand

- Availability

- Changeovers

- Performance

- Quality

Once we understand our losses, we can then focus on how to reduce them and maximise the asset utilisation.

The Key Steps are as follows:

- Appoint a site champion to lead this continuous improvement (CI) process

- Create an improvement team made up of Production, Maintenance and Reliability Engineering personnel

- Understand our Manufacturing pattern for production

- Quantify the losses in terms of time and money

- Identify the opportunity in terms of time and money

Once the data has been analysed we can identify Continuous Improvement opportunities and the best Continuous improvement teams within the facility. At this stage, we might want to categorise our improvement opportunities in terms of Reliability Excellence, Operational Excellence and Process Knowledge. See Figure 3 Project Examples

These teams may require some awareness training and support from external Continuous Improvement specialists to support their understanding of continuous improvement techniques such as:

- Waste Identification

- Root Cause Analysis (RCA)

- Solution Generation & Prioritisation

- Failure Modes Effects Criticality Analysis (FMECA)

- Vulnerability Analysis

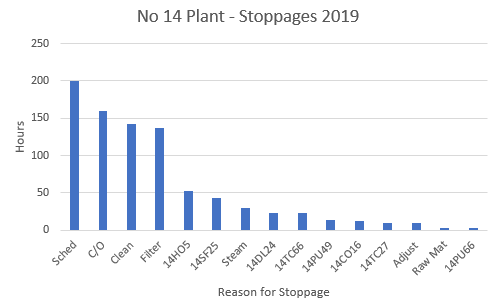

- Pareto Analysis (see figure 2)

In the Pareto above, the total hours lost on this plant in 2019 equalled 862 Hours of potential production time.

Develop a Project and Communication Plan

With the mini improvement projects identified, we need to then develop a project plan to track progress which can also be used as a method of communication with site leadership. Raising awareness of the projects across site will also require a good communication plan. Communication plans could involve different tiers of communication throughout the organisation and cover different means of communication.

| Utilisation Improvement Team – Reliability Excellence |

| Performed RCM Study to improve the reliability of No7 plant rotary drier. Availability increased by 12%Facilitated RCA on critical feed pump on No3 Plant – MTBF increased by 7500-hour calibration Issue corrected on level indicators on No2 Reactor allowing for increased batch sizes – 9% increase in batch optimized spares for No 4 plant to reduce waiting time for spares on critical asset list. – Eliminated waiting time by 336 hours this year |

| Utilisation Improvement Team – Operational Excellence |

| Calciner leaks causing raw material loss, seal upgraded, and new fixing arrangement installed. Throughput increased by 5%Removed the need for manual raw material testing at stage 1 on reactor 3 with an auto tester. Reduced batch waiting time by 1 hour. The changeover process from product A to product B was analysed and a new changeover procedure was developed, reduced change over time by 26 hours. |

| Utilisation Improvement Team – Process Knowledge |

| Stabilised the quality of the feed slurry to the rotary filter drum to reduce drying time by 20 hours a month |

Figure 2 – Project Examples

Celebrate Success

Let us not forget to celebrate when we have achieved our goals, we want this success to be recreated on the other improvement projects. Any changes that are required need to be sustainable to ensure the gains are not short-lived. We need to increase awareness and engagement in the improvement so that the new way of working becomes business as usual. We might need to create new Operating Procedures; including Business Process Maps to identify work patterns, roles and responsibilities.

Summary

The key to the success of Continuous Improvement projects is that they are just that, continuous. If not, the benefits you achieve will be relatively short-lived. The CI project needs to be kept alive so that the processes you have improved are reviewed continually and adapted as needed. This will maximise the benefits of your projects and avoid the need for larger-scale transformation which can potentially interrupt operations. A focus on asset utilisation using the various techniques described is just one area in which a business can identify these opportunities and show real benefits. Let us start to turn that hidden profit into actual profit.

Written by : Gary Tyne CRL of Pro-Reliability Solutions and Dr Mariesha Jaffray of MAJCI Ltd.

Authors Bio:

Mariesha has 25 years’ experience delivering continuous improvement and change management in academia, healthcare, and oil & gas. She is a Lean Six Black Belt and has a PhD in Change management. She coordinated OGUK’s Industry-led Efficiency Task Force and most recently supported the delivery of CNOOC’s programme of Continuous Improvement. She runs her own improvement company supporting organisations to optimise their business processes to eliminate waste and maximise quality, this ranges from the provision of training in the use of CI tools and methodology, improvement project mentoring to developing and implementing internal programmes of continuous improvement.

Gary boasts an extensive 35 year-career in the maintenance and reliability field. He has delivered various reliability programs, root cause analysis investigations, and maintenance and reliability training courses around the world. These are within numerous industry verticals such as oil and gas, pharmaceutical, food and beverage, chemical, automotive, and general manufacturing companies based both in the UK and overseas. He is also author and co-author of several reliability focussed papers and has presented papers at various global conferences.

gtyne@pro-reliabilitysolutions.com

Further Information

If you are interested in performing a Reliability Maturity Self-Assessment at your facility or would like to develop a roadmap for your Reliability future, then please get in touch.